1. Introduction

In the world of manufacturing, traditional models have long relied on a complex web of wholesalers, retailers, and distributors. This method, while effective for many years, often results in inefficiencies, higher costs, and a disconnect from the end consumer. Enter the Direct-to-Consumer (D2C) model—a transformative approach that allows manufacturers to bypass intermediaries and sell directly to their customers. This blog delves into the nuances of the D2C model, its benefits, implementation strategies, and future trends.

2. The Shift from Traditional Models to D2C

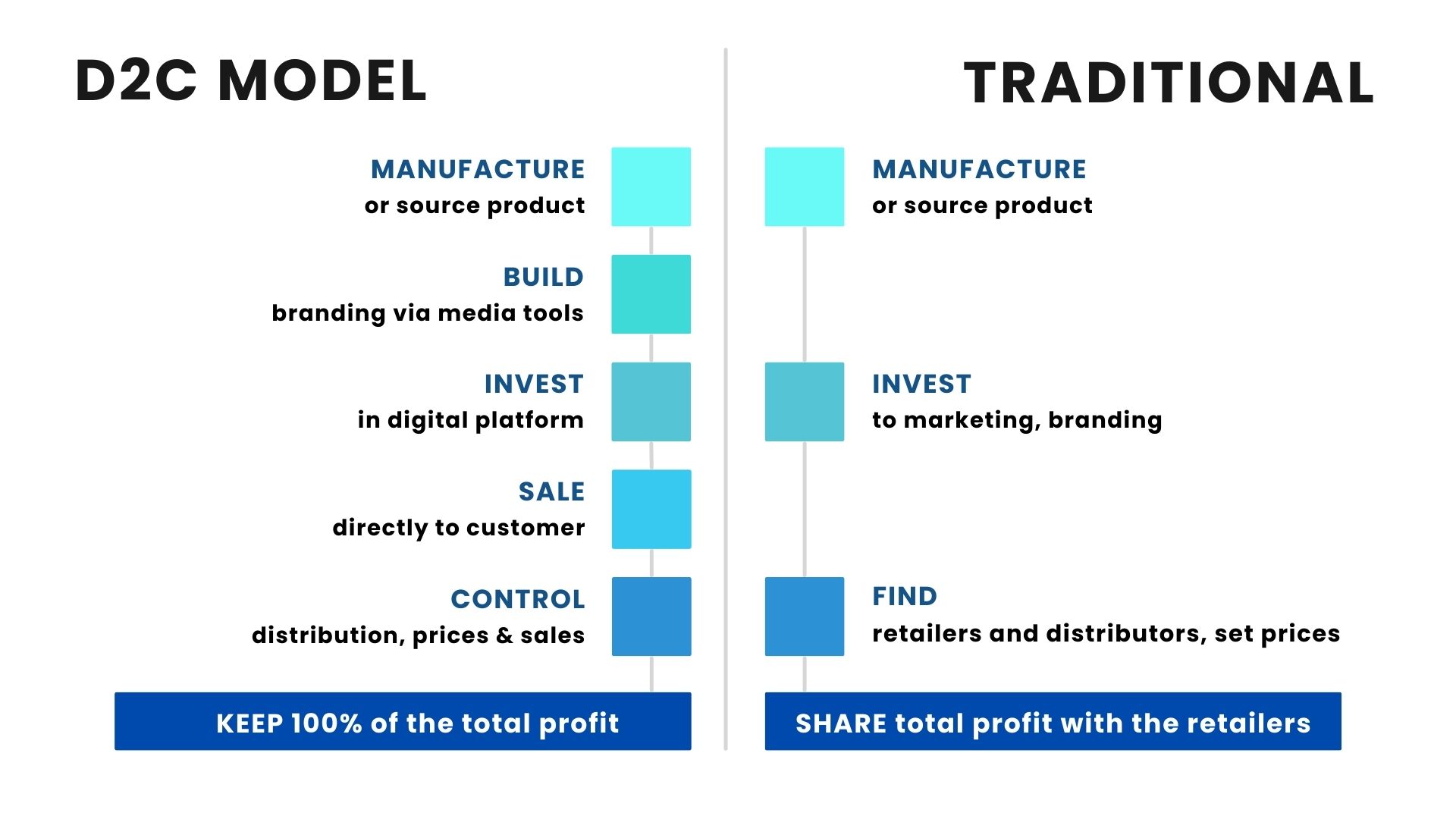

D2C vs Traditional Model

Traditional manufacturing and distribution channels are riddled with inefficiencies. High operational costs, dependency on third-party retailers, and delayed customer feedback are just a few of the challenges. For instance, a typical product must pass through multiple hands before reaching the consumer, each layer adding its margin, which ultimately inflates the end price and reduces profit margins for the manufacturer.

The D2C model eliminates these middlemen, allowing manufacturers to enjoy higher profit margins, direct access to customer data, and greater control over branding and customer experience. By selling directly to consumers, manufacturers can respond more quickly to market changes and customer demands, driving innovation and agility.

3. Benefits of the D2C Model for Manufacturers

Enhanced Customer Relationships

Direct customer interactions enable manufacturers to collect valuable data, understand customer needs, and deliver personalized experiences. This direct feedback loop fosters customer loyalty and allows for more effective marketing strategies. For example, D2C pioneer Glossier uses customer feedback to inform product development and marketing, resulting in a loyal customer base and a strong brand community.

Higher Profit Margins

Higher Profit Margins

By cutting out intermediaries, manufacturers can reduce costs and increase their profit margins. This financial advantage allows for more competitive pricing and higher reinvestment in the business. For instance, Warby Parker’s D2C approach enabled them to offer high-quality eyewear at a fraction of traditional retail prices, significantly disrupting the market.

Brand Control

Manufacturers retain full control over their brand image, marketing strategies, and customer interactions. This control ensures consistent messaging and a unified brand experience across all touchpoints. Brands like Nike, which has significantly invested in its D2C channels, benefit from a stronger brand presence and enhanced customer loyalty.

Agility and Innovation

With direct access to customer feedback, manufacturers can quickly adapt to market trends and customer preferences. This agility facilitates faster product development cycles and the ability to test and iterate new products and strategies. For example, Dollar Shave Club rapidly evolved its product line based on direct customer feedback, maintaining a competitive edge in the market.

4. Implementing a D2C Model in Manufacturing

Building an Online Presence

A robust online presence is crucial for D2C success. Manufacturers must invest in a user-friendly e-commerce platform that offers seamless navigation, mobile responsiveness, and secure payment systems. Key elements include high-quality product images, detailed descriptions, and customer reviews. Companies like Casper have mastered the art of a compelling online presence, making it easy for customers to browse, purchase, and review products.

Logistics and Supply Chain Management

Logistics and Supply Chain Management

Adapting supply chains to support direct shipping to customers is essential. This adaptation includes efficient inventory management, reliable delivery services, and real-time tracking. Implementing advanced logistics solutions can streamline these processes. For instance, Zappos’ commitment to fast, free shipping and hassle-free returns has set a high standard in D2C logistics.

Customer Service

Exceptional customer service is a cornerstone of the D2C model. Manufacturers must develop robust support systems that include chatbots, live chat, comprehensive FAQs, and easy-to-access customer service. Ensuring quick and effective resolution of customer issues can enhance the overall shopping experience and build long-term loyalty.

5. Challenges and Solutions in the D2C Transition

Production Scalability

Scaling production to meet increased demand without compromising quality is a significant challenge. Manufacturers can adopt lean manufacturing principles and flexible production systems to manage scalability. For example, Tesla’s use of automated production lines and just-in-time manufacturing processes allows for efficient scalability while maintaining high product quality.

Technology Integration

CRM Management

Implementing CRM systems, ERP software, and other technological solutions is critical for streamlining operations and enhancing customer interactions. These technologies enable better data management, process automation, and customer insights. Selecting the right technology partners and solutions, as seen in Nike’s collaboration with Salesforce for their CRM needs, is crucial for successful integration.

Related: CRM development and implement

Marketing and Customer Acquisition

Effective online marketing strategies are vital for attracting and retaining customers. Manufacturers should leverage SEO, content marketing, social media, and PPC campaigns to build brand awareness and drive traffic. Utilizing data analytics helps in creating targeted marketing strategies and improving customer segmentation. Glossier’s success in using social media and influencer marketing to build a strong brand following is a prime example.

6. The Future of D2C in Manufacturing

Emerging Trends

Technologies such as AI, IoT, and blockchain are transforming the D2C landscape. AI can enhance personalized marketing and customer service, while IoT can improve supply chain transparency and efficiency. Blockchain technology ensures secure and transparent transactions, fostering trust and reliability. These technologies will continue to evolve and shape the future of D2C models.

The Importance of IT Outsourcing

For D2C success, partnering with an IT outsourcing firm is crucial. IT outsourcing provides access to specialized expertise, reduces costs, and allows for scalability. An IT partner can develop and maintain essential software, such as e-commerce platforms, CRM systems, and data analytics tools. When choosing an IT outsourcing partner, manufacturers should consider the firm’s experience in the manufacturing sector and their technological capabilities. For example, partnering with IT giants like Infosys or TCS has helped many manufacturers streamline their IT operations and focus on core business activities.

Potential Challenges and Solutions

As the D2C trend grows, manufacturers may face increased competition and changing regulations. Staying competitive requires continuous innovation, investment in new technologies, and maintaining high standards of customer service. Manufacturers should also keep an eye on regulatory changes and adapt their strategies accordingly to ensure compliance and sustainability.

7. Conclusion

The D2C model offers manufacturers numerous benefits, including higher profit margins, enhanced customer relationships, and greater brand control. By embracing technology and forming strategic partnerships, such as IT outsourcing, manufacturers can successfully transition to a D2C model and stay ahead in the competitive market. The future of manufacturing is increasingly leaning towards direct consumer engagement, and now is the time for manufacturers to explore and adopt D2C strategies.